vickers hardness test wikipedia|vickers hardness test explained : distributors The Vickers hardness test or the 136 degree diamond pyramid hardness test is a . Resultado da Login. Only School Life / Romance QuaIngSook | Momobird. A Porta de Entrada do Excluído. Meu nome é Kaleb e eu sempre fui excluído. Mas, .

{plog:ftitle_list}

webOnline sports betting | Games, Props, Live Betting, eSports | Top Welcome Bonus and regular Reload Bonus offers | Low margins | Secure deposits | 24h Customer Service | .

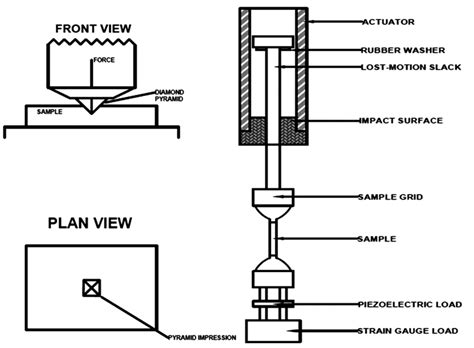

vickers hardness testing machine diagram

Mohs hardness [1] Vickers hardness (MPa) [1] Brinell hardness (MPa) [1] Brinell . A variety of hardness-testing methods are available, including the Vickers, Brinell, .The Vickers hardness test or the 136 degree diamond pyramid hardness test is a .

The Vickers method has a test load range from 1 gf according to ISO respectively from 1 gf up to 120 kgf according to ASTM, which means that this method can be used for hardness testing across all load ranges (from the micro to the low .

The Vickers hardness test is a test performed to measure the hardness of .

The Vickers hardness test was developed in 1921 by Robert L. Smith and .Vickers Hardness Testing Formulas, Calculator and Review. The Vickers test can be used for all metals and has one of the widest scales among hardness tests. The unit of hardness given by the test is known as the Vickers Pyramid .A Vickers hardness tester. There are three main types of hardness measurements: scratch, .

The Vickers hardness test was developed in 1921 by Robert L. Smith and George E. Sandland at Vickers Ltd as an alternative to the Brinell method to measure the hardness of materials. The Vickers test can be used for all metals and has one of the widest scales among hardness tests. The unit of hardness given by the test is known as the Vickers Pyramid .

15.2.3.2 Hardness Test. A Vickers hardness testing machine was employed to determine the hardness differences of all the rolled strip specimens in the thicker, thinner, and transition zones by applying a load of 1 N with a dwelling time of 12 s. Hardness measurements were performed on the cross-section surfaces of the rolled strips along the .Angles of a Knoop hardness test indenter. The Knoop hardness test / k ə ˈ n uː p / is a microhardness test – a test for mechanical hardness used particularly for very brittle materials or thin sheets, where only a small indentation may be made for testing purposes. A pyramidal diamond point is pressed into the polished surface of the test material with a known (often 100 .

The point of a hardness scale is the comparison of materials to each other. In other words a difference of a (multiplicative) constant divides out when comparing materials. It is said that the Vickers hardness is not a pressure, but it seems to me to be proportional to a pressure, and therefore a pressure.Hardness test methods in the macro range include Brinell, Vickers and Rockwell. Hardness testing in the low-load range applies when the test load falls between an interval of 0.2 kgf and 5 kgf (test load ≥ 0.2 kgf and < 5 kgf). The most commonly used low-load method is Vickers. Low-load hardness testing is mainly used for testing of small . The Vickers Hardness test (ISO 6507) is used to characterize hardness of various solid materials (metals, ceramics, etc.). A diamond pyramid is pressed against the solid with a certain normal load and the hardness is calculated based on the imprint left on the surface.The Leeb Rebound Hardness Test (LRHT) invented by Swiss company Proceq SA is one of the four most used methods for testing metal hardness.This portable method is mainly used for testing sufficiently large workpieces (mainly above 1 kg). [citation needed]It measures the coefficient of restitution.It is a form of nondestructive testing.

Media in category "Vickers hardness test" The following 20 files are in this category, out of 20 total. Case hardened steel-vickers hardness test.png 640 × 480; 303 KB. Chromizing.jpg 2,592 × 1,944; 364 KB. Durete vickers.png 402 × 481; 12 KB. Hardheid volgens Vickers.png 402 × .The Brinell hardness is designated by the most commonly used test standards (ASTM E10-14 [2] and ISO 6506–1:2005) as HBW (H from hardness, B from brinell and W from the material of the indenter, tungsten (wolfram) carbide). In former standards HB or HBS were used to refer to measurements made with steel indenters.

vickers hardness test theory

ISO 6507-4: Metallic materials – Vickers hardness test – Part 4: Tables of hardness values; ISO 18265: Metallic materials – Conversion of Hardness Values; Pranala luar. Video on the Vickers hardness test; Vickers hardness test; Conversion table – Vickers, Brinell, and Rockwell scales Halaman ini terakhir diubah pada 20 Desember 2022 .Máy kiểm tra độ cứng Vickers. Phép kiểm tra độ cứng Vickers đã được phát triển năm 1921 bởi Robert L. Smith và George E. Sandland tại Vickers Ltd, là một sự thay thế cho phương pháp Brinell để đo độ cứng của vật liệu. Phép kiểm tra Vickers thường dễ sử dụng hơn các phép kiểm tra độ cứng khác, vì các phép tính .A Rockwell hardness tester. The Rockwell scale is a hardness scale based on indentation hardness of a material. The Rockwell test measures the depth of penetration of an indenter under a large load (major load) compared to the penetration made by a preload (minor load). [1] There are different scales, denoted by a single letter, that use different loads or indenters.The Barcol hardness test characterizes the indentation hardness of materials through the depth of penetration of an indentor, loaded on a material sample and compared to the penetration in a reference material. The method is most often used for composite materials such as reinforced thermosetting resins or to determine how much a resin or plastic has cured.

ビッカース硬さの測定法の略図。黄色の部分はダイアモンド付きの測定子. ビッカース硬さ(ビッカースかたさ、英: Vickers hardness 、単位:HV)は、硬さを表す尺度の一つであり、押込み硬さの一種である。 ダイヤモンドでできた剛体(圧子)を被試験物に対して押込み、そのときにできるくぼみ .

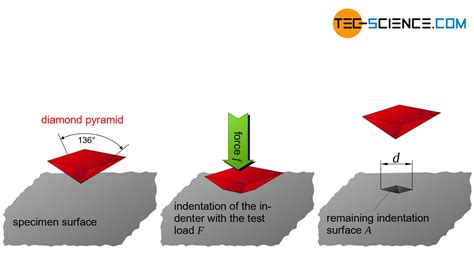

Implementation File:Vickers-path.svg Vicker's test scheme. The Vickers hardness test uses a diamond, with the shape of square-based pyramid with an angle of 136° between opposite faces as an indenter (22° between the indenter face and surface).It is based on the principle that impressions made by this indenter are geometrically similar regardless of load.The Vickers hardness test is ideal for testing of all metals and is therefore the method with the widest range of application. The hardness test method according to Vickers is described in standards ISO 6507 (Metallic materials – .The Vickers hardness test is often regarded as easier to use than other hardness tests: The process can be performed on a universal or micro hardness tester; the required calculations are independent of the size of the indenter; .3.2 Conducting the Test. Positioning the Sample: Secure the material sample in the testing machine.; Selecting the Indenter: Choose the appropriate ball diameter based on the material hardness.; Applying the Load: Gradually apply the specified load using the machine.The load should be maintained for a predetermined dwell time, usually between 10 to 15 seconds.

The Vickers hardness tester Wiki 200 JS is a fully automatic and motorized hardness testing machine with test loads from 0,001 to 100 kgf. It is suitable for CHD (Case Hardness Depth) tests on multiple samples. Wiki 200 JS is conform to ASTM and ISO hardness testing standard.ISO 6507-1:2018 specifies the Vickers hardness test method for the three different ranges of test force for metallic materials including hardmetals and other cemented carbides. General information. Status : Withdrawn. Publication date : 2018-01. Stage: Withdrawal of International Standard Edition : 4. Number of pages .

The Vickers hardness test was developed as an alternative to the Brinell method to measure the hardness of materials. The Vickers test is often easier to use than other hardness tests, since the required calculations are independent of the size of the indenter, and the indenter can be used for all materials irrespective of hardness. The basic principle, as with all common measures of .Advantages of the Vickers Hardness Test. The Vickers hardness test is esteemed for several reasons: Versatility: It can be used for all metals, unlike some tests that are limited to specific types or hardness ranges. Precision: The test can target very small parts or thin materials with minimal surface damage.The Vickers hardness test was developed in 1921 by Robert L. Smith and George E. Sandland at Vickers Ltd as an alternative to the Brinell method to measure the hardness of materials. [1] The Vickers test is often easier to use than other hardness tests since the required calculations are independent of the size of the indenter, and the indenter can be used for all materials .

The Vickers hardness test method, also referred to as a microhardness test method, is mostly used for small parts, thin sections, or case depth work. The Microhardness test procedure, ASTM E-384, specifies a range of light loads using a diamond indenter to make an indentation.

The Palmqvist-method uses the lengths of the cracks from a number of Vickers indentions to determine the fracture toughness. The Palmqvist fracture toughness is given by [2] = in units of MPa, where HV is the Vickers hardness in N/mm 2 (or MPa) (i.e., 9.81 x numerical HV), P is the indentation load in N (typically 30 kgf is used) and T is the total crack length (mm) after .

The Vickers hardness test is a test performed to measure the hardness of materials, specifically thin sections and small parts. It is comprised of a diamond indenter and a light load to produce an indentation on the subject under testing. The depth of indentation is converted into the hardness value of the object.維氏硬度測量儀. 維氏硬度試驗(英語: Vickers hardness test ),是壓入硬度試驗之一種,其測量值用HV表示。. 維氏硬度試驗最初於20世紀20年代初被提出,比起其他硬度試驗其優點有:硬度值與壓頭大小、負荷值無關;無需根據材料軟硬變換壓頭;正方形的壓痕輪廓邊緣清晰,便於測 .

Resultado da Sign up for Deezer and listen to Aud-20221105-Wa0000 by Harkov and 120 million more tracks.

vickers hardness test wikipedia|vickers hardness test explained